Multiskilled Manufacturer Finnpelti Even More Versatile with SafanDarley Sheet Metal Machines

The name Finnpelti reflects only a small part of the capabilities of this Sastamala-based company, as its service range covers a wide range of steel expertise from thin sheets to heavier metalwork, complemented by the company’s own products. As the latest step in their development, this family business acquired a SafanDarley sheet metal cutter and hybrid press brake to expand their sheet metal offerings even further.

Finnpelti’s deliveries are sealed with their in-house transportation fleet, featuring a playful summary of the company’s expertise on one of the delivery vehicles: “We think we know… machining… sheet metal work… surface treatment… roof and sheet metal products… welding…”. This company has an exceptionally strong set of supporting pillars, and the company’s own products such as snow guards, rafter systems, trailer hitches, roof and sheet metal products, as well as stools and furniture are the cherry on top. In addition, the whole package includes an HVAC store in the center of Vammala and its two installers. This comprehensive package amounts to approximately €4 million in revenue.

The company began its work in sheet metal construction in 1992, and under its current legal form, it has operated since 1999. Over the years, the service range has expanded from sheet metal work to the current offering. Today, it is a “general store in the metal industry,” says Seppo Karimäki, the company’s founder and CEO.

Everything from metal with its own paint shop

In practice, they manufacture everything from metal, including building metal parts and roof profiles with their very versatile machine fleet, as well as subcontracting metalwork. As a subcontractor, they can offer a comprehensive range of machines: sheet metal cutters, laser and waterjet cutting machines, press brakes, and in machining, machining centers, lathes, and, most recently, a wire saw. With this wide range of machines, they can serve material thicknesses from 0.1mm to 100mm. They also have a good set of machines for welding, including robot welding. Their in-house powder coating shop completes the package. When all this expertise is under their control, they can guarantee the quality and ensure that parts made using different manufacturing methods fit together accurately. Their reliability and quality have earned praise from their customers.

They also invest heavily in their own material inventory, allowing them to respond quickly to customer needs, even on short notice.

Skilled professionals

Finnpelti Oy’s exceptional range of steel expertise has built a customer base of hundreds, which is served by 18 people. “We have many long-term employment relationships, and this team has both robust professional skills and great flexibility to ensure flexible customer service,” says production manager Sami Karimäki.

Increased capabilities with SafanDarley sheet metal machines

Among Finnpelti Oy’s very versatile machine arsenal, there are also many special machines. They even have an automated production line that was custom-built to meet the specific needs of Finnpelti Oy for manufacturing sheet metal parts.

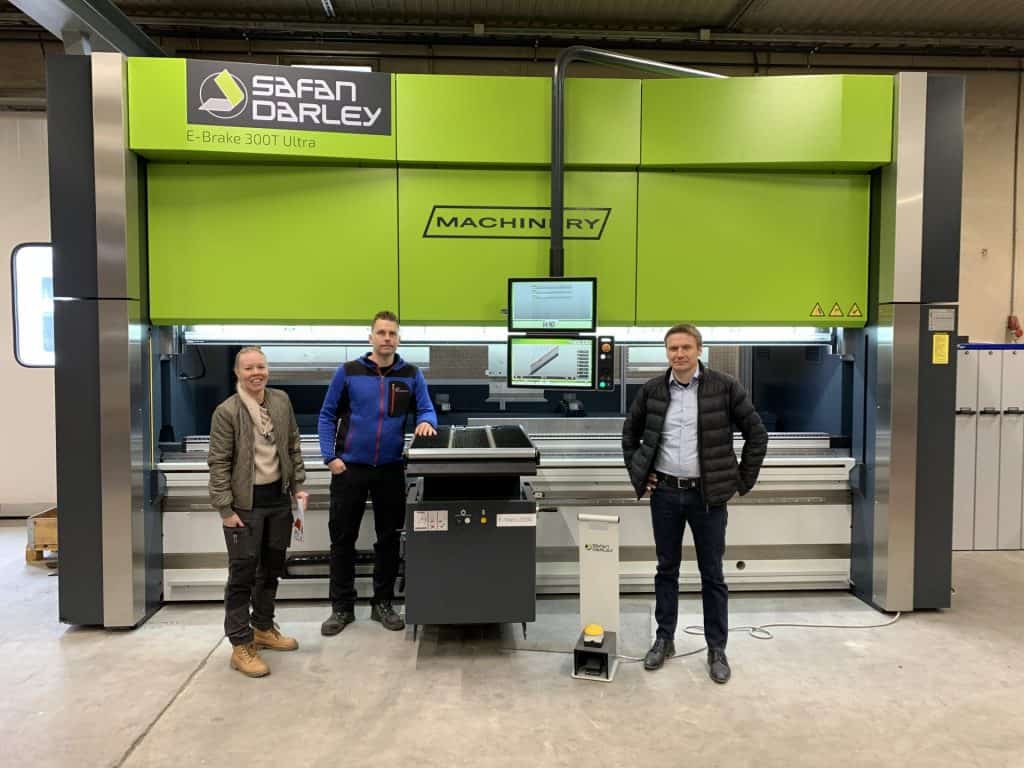

Even the latest machines from the company, SafanDarley sheet metal cutter and hybrid press brake, were tailored to meet the needs of the Karimäki family business. “SafanDarley’s machines are always customized to the needs of the customer, thanks to hundreds of different machine-specific customization options from this Dutch manufacturer. The only feature that cannot be customized in servo models is the machine size,” explains Kalle Louhimo, who sold the machines to Finnpelti Oy.

Louhimo receives a lot of praise from the Karimäki family, both the father and the son. “When buying these machines, we surveyed all the brands, and Kalle, as the seller of the SafanDarley machines, was able to justify the precision of SafanDarley machines. These are not the cheapest machines in the sector, but we have done a lot of business with Kalle, and his operations have convinced us: Kalle never leaves us in the lurch; we always get help from him whenever we need it—whatever time of the day it may be.”

“We were convinced by the speed of the fully electric SafanDarley MShear sheet metal cutter. The SafanDarley E-Brake 300T hybrid press brake gives us an additional 300-ton machine for bending, and thanks to its servo operation, it also provides precision in bending tasks. This further increases our capabilities as a manufacturer of accurate parts,” says Sami Karimäki.

Sheet metal cutters are becoming increasingly rare investments today, with the growing popularity of laser cutting machines. “In many cases, mechanical sheet metal cutting is cheaper than laser cutting. That’s why we continue to invest in it, and we wanted to strengthen this sector further with SafanDarley,” explains Sami Karimäki.

Finnpelti Oy’s new SafanDarley press brake is equipped with features like laser angle monitoring and automatic front support. The new sheet metal cutter also has unloading locations to the front, rear, or directly below.

Daring to invest in machines

“Our employees have exceptionally broad professional skills covering the entire range of the metal industry. This expertise can be fully utilized only with versatile, state-of-the-art machines. We have always moved forward and dared to invest in machines. Work is enjoyable when we have good machines to work with,” says Sami Karimäki.

New Horizons

The coronavirus era has reduced Finnpelti Oy’s revenue by about ten percent, but the company looks forward to the future with a positive outlook. “We continue to develop our operations systematically, step by step. The generational change process has been underway for some time, and we are progressing with careful planning,” says Seppo Karimäki.

In the summer, the company enters a new phase when their first external CEO takes on their role. We still have a lot of potential and machine capacity at our disposal, and when the new CEO takes on their role, it is intended to push things forward again, concludes production manager Sami Karimäki.

News

Machinery Ltd will be divided into two independent companies: Machinery Ltd and Machinery MT Ltd – The goal is to enhance customer orientation and simplify internal processes

Read moreNews

BOREO STREAMLINES ITS ORGANIZATIONAL STRUCTURE TO ENHANCE BUSINESS SERVICE CAPABILITIES

Read more