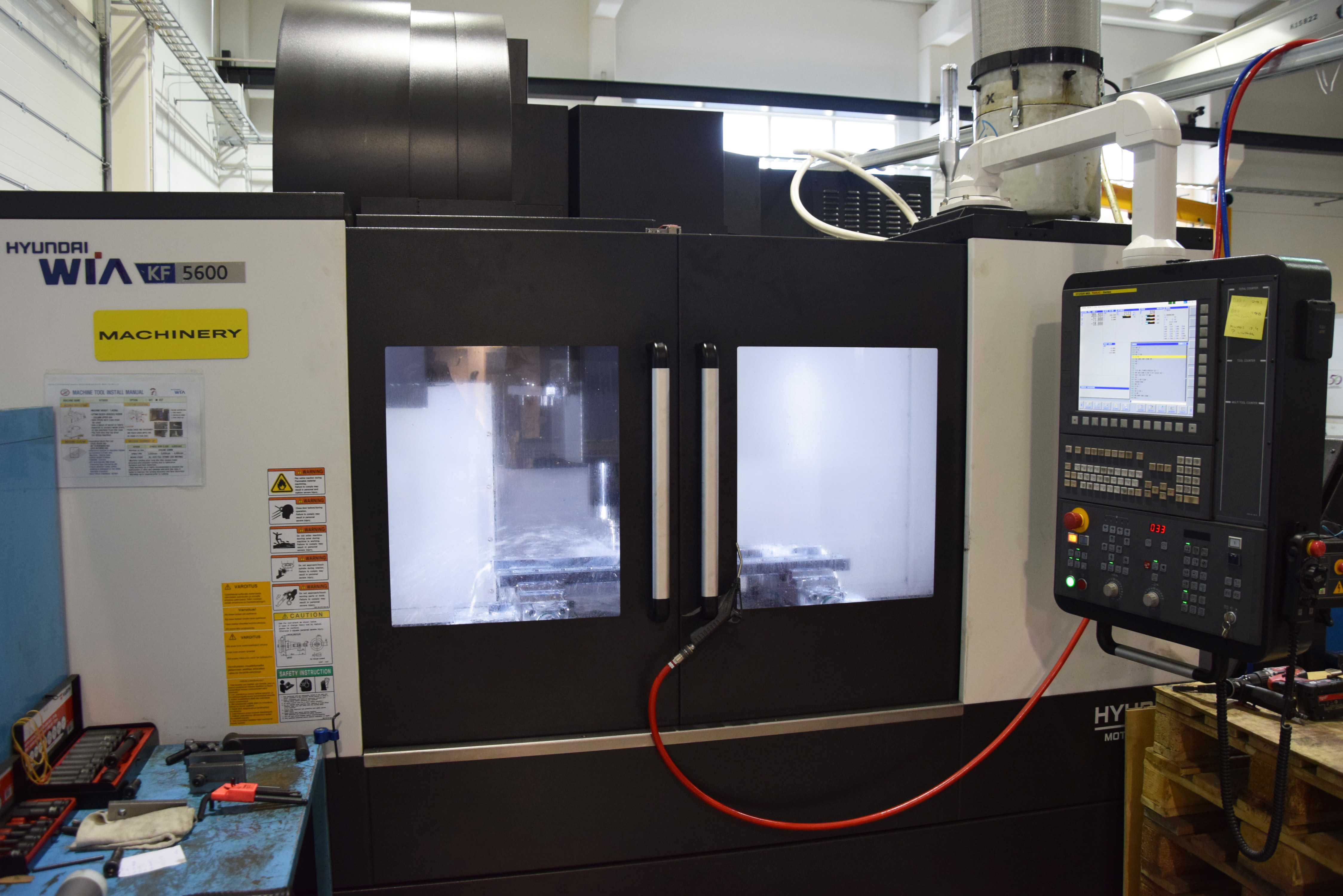

Expanding Milling Capacity For Jokke-Koneistus – Heavy-Duty Vertical Machining Center Delivered in Record Time

The faster, the better, thought Jokke-Koneistus at the beginning of the year when the company needed to quickly supplement its machining center’s capacity. The Hyundai-Wia KF5600 was in operation at the company within a week of the order.

Jokke-Koneistus Oy is a machine shop located in Ähtäri. Subcontracting work is done, with a few major customers and a whole host of smaller ones in various industrial sectors. The company was founded by Jouko Paloneva, who worked as a teacher in a vocational school in 1989. The company started as a side job for the teacher, but customers were found, and work increased early on to such an extent that side work soon became the main work.

Over the years, one CNC lathe has grown into a comprehensive and versatile metal subcontracting company. “Customers appreciate service from one source. We handle machining, milling, turning, and high-speed machining in-house, and our network serves other related functions. This also allows us to handle sheet metal work, coatings, and hardening, for example,” says Kalle Paloneva.

Kalle Paloneva has been leading the company since the generational change in 2010. The second owner of the family business is his brother, Ville Paloneva. Asko Virolainen is also a partner in the company. Jokke-Koneistus operates in Ähtäri in an expanded hall from the mid-2010s, with ample space for a large material warehouse.

“Expertise, efficiency, and delivery speed are the elements of success. They are required to deliver parts to customers in a quality and on a predetermined schedule,” says Kalle Paloneva.

Increased milling work

Jokke-Koneistus handles a variety of tasks, but its operations have traditionally emphasized axial production. In addition to turning work, there has been plenty of work in milling recently, and with increased demand, the company has also added more machines in this sector. Milling can be done up to the size of five meters.

At the beginning of the year, Jokke-Koneistus needed to replenish its milling capacity, and the work dictated that the faster the new machining center would be put into operation in Ähtäri, the better. Machinery is one of Jokke-Koneistus’s machine suppliers, and by the beginning of this year, two Hyundai-Wia machines, the F650/50 machining center, and the large machining CNC lathe L700MA, have already been delivered to the company in two years.

“Hyundai-Wia machines, their support and service functions have been a positive experience for us. As a result, attention to the purchase of this new machining center quickly turned to the same machine manufacturer,” says Paloneva.

A call to Machinery found a solution ready for quick delivery from Koneareena in Tampere, the new series of Hyundai-Wia vertical machining center KF5600. “The matter had to be thought about for a moment because we initially considered a slightly larger machine. However, quick delivery was decisive, and that was it. The machine arrived here quickly, and the chips were already flying a week after the order,” says Paloneva.

A Robust and Fast Package

The KF5600 represents Hyundai-Wia’s updated range, and the machine’s work area is now larger than its previous generation; the X-axis movement is now 1100 mm, Y 560 mm, and Z 520 mm. It also comes with built-in BBT40 15,000 rpm high-speed machining and linear roller guides. The robust machine is also faster than before in rapid movements and tool changes.

“One key change from the past is improved chip removal. Thanks to the design of the machine’s work area guards, chips can be efficiently removed from the work area,” says Kari Raivonen from Machinery.

Kalle Paloneva says that the fast delivery of the machine was the core of the acquisition, but after installation, the machine has also proven to be a sound choice in other ways. “In fact, it is just the right machine for us. We have noticed the machine’s speed and rigidity as positive factors. Rigidity means precise machining,” says Kalle Paloneva.

Jokke-Koneistus has plenty of work. The COVID-19 period has not affected the company’s activities, and the future also looks promising. The company, which now employs 12 people, has an annual turnover of about 2.2 million euros. “Of course, you cannot predict things for a very long time, but at least the end of the year looks like a strong time to work. The prices of raw materials have risen rapidly, but hopefully, the situation will stabilize in that regard. In any case, the positive atmosphere continues,” says Paloneva.

Investments in Ähtäri also continue, and the milling machine fleet will be further updated later this year. One new, larger machining unit is on order.”

The news was originally published on June 14th in Konekuriiri, with Kari Harju as the author.

News

Machinery Ltd will be divided into two independent companies: Machinery Ltd and Machinery MT Ltd – The goal is to enhance customer orientation and simplify internal processes

Read moreNews

BOREO STREAMLINES ITS ORGANIZATIONAL STRUCTURE TO ENHANCE BUSINESS SERVICE CAPABILITIES

Read more